Bote Optics Advanced Manufacturing

Learn by Category

PRECISION OPTICS, LASER OPTICS, OPTICAL FILTERS, IMAGING OPTICS

PRECISION OPTICS

IMAGING OPTICS

LASER OPTICS

OPTICAL FILTERS

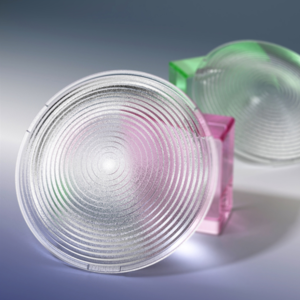

One Stop Lens and Mirrors Solution

Bote Optics (S) Pte Ltd is a premier high-tech enterprise based in Singapore, specializing in cutting-edge optics and lens manufacturing and coating solutions.

Since our inception in 2005, we have been at the forefront of delivering superior optica lenses products and services to a global clientele, continually pushing the boundaries of lens optic innovation.

Manufacturing Techniques

BOTE is in a period of rapid development. In order to meet your high standard needs, BOTE introduces the industry’s top processing and testing equipment every year. Some devices as follow:

- Ion Beam Sputtering (IBS)

- Thermal Evaporation

- High-Precision Optical Monitoring

- Hard Coatings for Stringent Environments and Durability

- Automated Ultrasonic Cleaning

- Grinding

- Polishing

- Diamond Turning

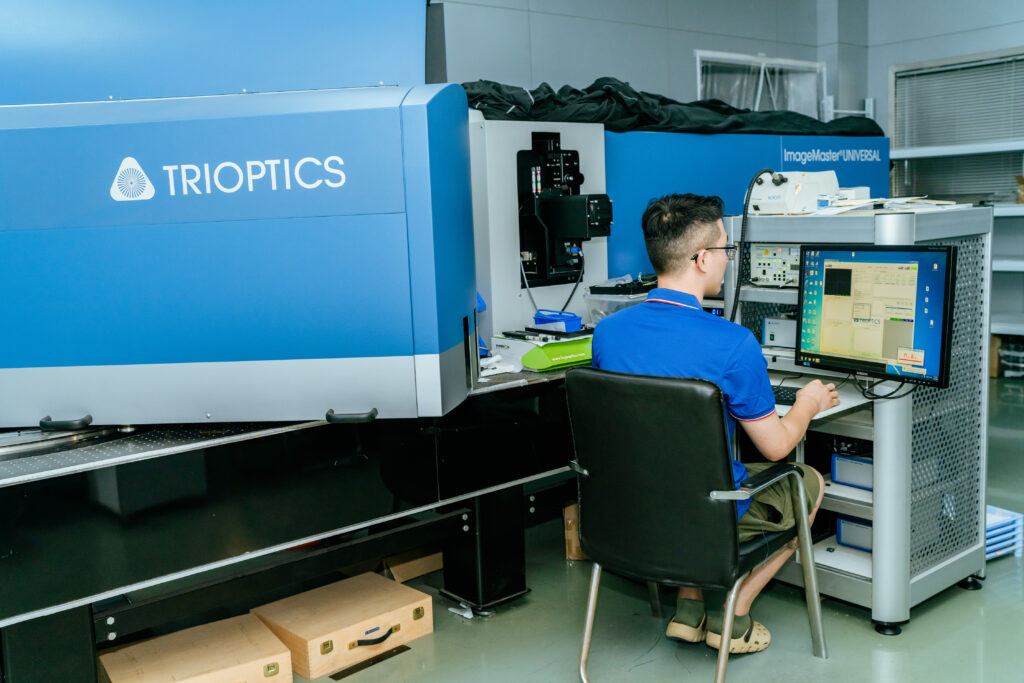

State-of-the-Art Metrology

High-end Metrology is necessary to complete high-standard customized optical projects. With the help of the metrology and tools, it can not only improve work efficiency, but more importantly, it can help us accurately judge and discover problems. Only by finding the root of the problem can we effectively solve the problem.

Some devices and tests as follow:

- Spectrophotometers – Agilent

- ZYGO NewView™ 6000 for surface roughness metrology

- Environmental test: temperature, humidity, salt spray

Engineering Services

Bote Optics will provide you with comprehensive services such as optical consulting, design, prototyping, after-sales technical support to ensure that your project is successfully put into use

Consulting and Design

- Bote Optics provides professional advice to help you optimize solutions and reduce costs.

- Wide Range of Design Tools

- Zemax, Abaqus FEA, Solidworks, Matlab®, and more

Consulting and Design

The technical team at Bote, led by a doctorate in optical and optomechanical, has rich experience in design, processing, optomechanical assemblies, after-sales support and can provide technical services to customers at any time for debugging and delivery.

- Optics Prototyping delivery in just 2-3 weeks

- Fast Custom Components

- Lead times as short as 3 weeks for custom glass optics depending on drawing and component type

Prototyping

Over 50 common glass types kept on factory

Custom Optical Assemblies

Quickly modify mechanics, magnification, or wavelength of off-the-shelf assemblies

FAQ

As early as the 9th century, Abbas Ibn Firnas, an inventor among many other things, developed the first corrective lenses. These lenses were shaped and polished into round “reading stones.” Jump to the thirteenth century, and glasses made their first known recorded appearance in Italy.

Lenses are the optical components that form the basic building blocks of many common optical devices, including cameras, binoculars, microscopes, and telescopes. Lenses are essentially light-controlling elements and so are exploited for light gathering and image formation.

Optical components have different processing methods according to customer requirements and materials. Common processing methods include blanking, grinding, polishing, and coating. There are also processing methods such as glass molding, diamond turning, and plastic injection molding.

Precision optics are optical components of various geometries and materials. They are used in optoelectronics, electro-optics, and optomechanical systems for light imaging, sensing, detection, and transmission applications in different wavelength bands

There are lots of precision optics corporation in the global. Founded in 2003, Bote is a company specializing in the research and development of precision optical components. Bote has 3 wholly-owned subsidiaries in Singapore and mainland China, exports to 50 countries overseas, and has an annual output of up to 500,000 pieces of various lenses and optical lenses.

- Lenses are transparent, mirrors are completely reflective – mirrors are a piece of transparent substrate with their backside coated with an opaque reflective metal amalgam. A lens is a completely transparent piece of substrate that bends light that passes through with an inward or outward bending surface.

- Mirrors reflect light while lenses refract light – Light beams that strike a mirror’s surface are bounced away in a different direction to form an image of the object in front of it. Lenses on the other hand let light pass through them to be bent.

- Mirrors have 1 important surface while lenses have 2 – Mirrors are plane (flat) or spherical (curved) with one reflective surface. Lenses have 2 surfaces that both affect the light that passes through.

- Lenses follow the laws of refraction while mirrors follow the laws of reflection.

- A mirror reflects 100% of the light that bounces on its reflective surface while a lens refracts or bends all of the light that passes through it.

- Image formation formula in a mirror: 1v+ 1u= 1f. Image formation in a lens: 1v- 1u= 1f.

- Plane mirrors do not have a focal point while lenses have 2 focal points in F and 2F.

Modern compound microscopes are designed to provide a magnified two-dimensional image that can be focused axially in successive focal planes, thus enabling a thorough examination of specimen fine structural detail in both two and three dimensions.

Most microscopes provide a translation mechanism attached to the stage that allows the microscopist to accurately position, orient, and focus the specimen to optimize visualization and recording of images. The intensity of illumination and orientation of light pathways throughout the microscope can be controlled with strategically placed diaphragms, mirrors, prisms, beamsplitters, and other optical elements to achieve the desired degree of brightness and contrast in the specimen.

Passive optical components are devices or elements used in optical systems that do not require external power or active control to perform their function. These components manipulate light signals through processes such as transmission, reflection, polarization, coupling, splitting, filtering, and attenuation.

With the rapid development of China’s semiconductor industry, new energy vehicles and artificial intelligence, the demand for optical components is also showing rapid growth. According to BOTE, although competition among optical component manufacturers is fierce, the scale and profitability of most manufacturers have increased in the past three years.

The global passive optical components market is projected to be valued at US$ 148.0 billion by 2032. It reached a valuation of US$ 45.5 billion in 2022.

In the field of precision optical components, the price of lenses depends on factors such as material, quantity, processing accuracy, and size. A cheap lens may cost just a few US dollars, and a high-end lens may cost more than 10,000 US dollars.