Showing 17–32 of 35 results

-

- Thickness Tolerance (%): ±40

- Dimensional Tolerance (inches): ±0.05

- Substrate: Acrylic

- Coating: Uncoated

- Wavelength Range (nm): 400 – 1100

- Index of Refraction nd: 1.49

- Transmission (%): 85 (Typical)

- Operating Temperature (°C): 80 (Maximum)

-

- Materials: Optical glass、optical crystal and others

- Diameter(mm): 5-500

- Diameter Tolerance(mm): ±0.03

- Thickness Tolerance(mm): ±0.03

- Surface finish (American standard) : 60-40或10-5

- Surface accuracy: λ/10@632.8nm or higher

- Focal length error: ±2%

- Clear Aperture: >90%

- Eccentricity: ≤3 arcmin or higher

- Bevel: 0.2mmX45°

- Coating: Customization

-

- Materials: Optical glass、optical crystal and others

- Diameter(mm): 5-500

- Diameter Tolerance(mm): ±0.03

- Thickness Tolerance(mm): ±0.03

- Surface finish (American standard) : 60-40或10-5

- Surface accuracy: λ/10@632.8nm or higher

- Focal length error: ±2%

- Clear Aperture: >90%

- Eccentricity: ≤3 arcmin or higher

- Bevel: 0.2mmX45°

- Coating: Customization

-

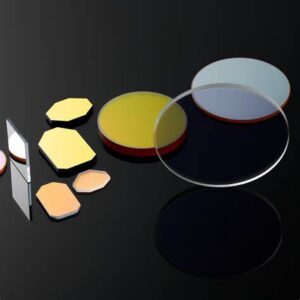

- Materials: zinc selenide, zinc sulfide, silicon, germanium, gallium arsenide, calcium fluoride, barium fluoride and chalcogenide

Design Wavelength: 10.6μm or customization

Focal Length Error: ±1%

Appearance Tolerance: +0.0/-0.1mm

Thickness Tolerance: ±0.1mm

Surface Quality: λ/2@632.8nm

Surface Smoothness : 40-20

Eccentricity: <3′

Clear Aperture: >90%

Bevel: <0.2×45°

Coating:10.6um AR,8-14um Broadband AR

-

- Thickness (mm): 1.00 ±0.2

- Angle of Incidence (°): 0

- Optical Density OD (Average): ≥3.0

- Coating: Traditional Coated

-

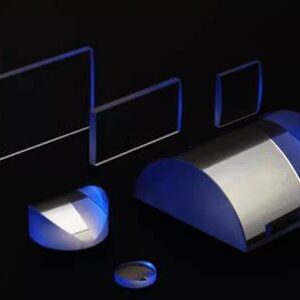

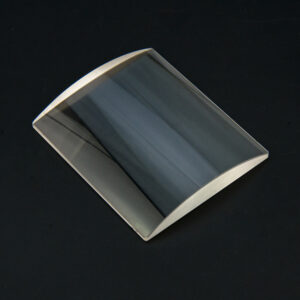

- Ideal for Multispectral Focusing Applications

- Variety of Coating Options Offered

- Multiple Sizes Available

- λ/8 Precision Spherical Mirrors Also Available

- Back Surface: Ground

- Focal Length Tolerance (%): ±2

- Surface Quality: 60-40

- Surface Accuracy: λ/4

-

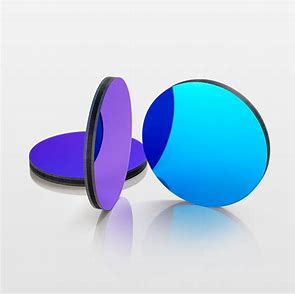

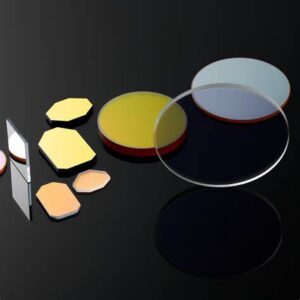

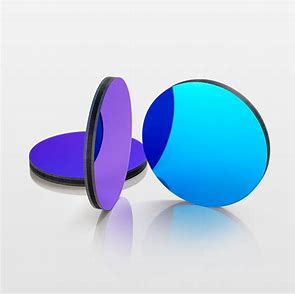

- Stop band range: 200 nm-1100 nm, 200 nm-1200 nm

- FWHM=3±0.6 nm, 10±2 nm, 25±3 nm, 50±5 nm

- 25.4 mm outer diameter with mechanical snap ring

- Center wavelength: 405-1064 nm

- Material Schott Borofloat & Soda Lime

- Stopband optical density>OD 4

- Diameter Ø25.4 mm

- Clear aperture : Ø22.0 mm

- Surface finish (scratches/pits) : 80/50

-

- Materials: UV fused Silicon

Diameter: 25.4 mm

Thickness: 6 mm

Coating: High energy laser line reflective film

Reflection: Rs,Rp>99%@Designed wavelength

AOI:0-45°

Thickness Tolerance: ±0.25 mm

Diameter Tolerance: +0.0/-0.1 mm

Surface Finish(@633 nm)λ/10

Surface Smoothness: 10/5

Parallelism: <3 arcmin

Back Surface: precision frosted finish

-

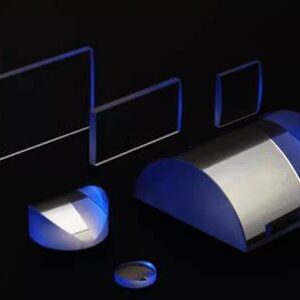

- Optional materials: K9, N-BK7, JGS series UV fused quartz

- Working range: 400 nm-700 nm (other bands can be customized)

- Design wavelength: 546.1nm(n=1.519)

- Focal length tolerance: ±2%

- Shape tolerance: +0.0/-0.02mm

- Thickness tolerance: ±0.02mm

- Curved aperture: 3

- Plane flatness (aperture): 1

- Curved surface local aperture: 0.5

- Eccentricity: ≤3 arcmin

- Surface shape: 1/4λ@632.8nm

- Surface finish: National standard level 3, US military standard 60-40

- Clear aperture: >90%

- Safety edge: <0.2X45°

-

- Materials: UV fused Silicon

- Diameter: 25.4 mm

- Thickness: 6 mm

- Coating: High energy laser line reflective film

- Reflection: Rs,Rp>99%@Designed wavelength

- AOI:0-45°

- Thickness Tolerance: ±0.25 mm

- Diameter Tolerance: +0.0/-0.1 mm

- Surface Finish(@633 nm)λ/10

- Surface Smoothness: 10/5

- Parallelism: <3 arcmin

- Back Surface: precision frosted finish

-

- Back Surface: Commercial Polish

- Surface Quality: 60-40

- Coating Type: Metal

-

- Optical element material: UV fused silica

- Plane flatness: (@633 nm) λ/2

- Curved surface local aperture: 0.5

- Eccentricity ≤3 arcmin

- Surface finish (scratches/pits): 40/20

- Design wavelength: 587.6 nm

-

- Materials: N-SF11

- Diameter: 12.7 mm

- Diameter Tolerance: +0.00/-0.10 mm

- Clear Aperture: 90% CA

- Center thickness: 3.0 mm

- Center thickness tolerance: ±0.1 mm

- Edge thickness: 4.9 mm

- Radius of curvature: -11.7 mm

- Design wavelength: 587.6 nm

- Working wavelength: 400 nm-700 nm

- Focal length: -15.0 mm

- Focal length diameter: ±1%

- Back focal length: -16.7 mm

- Coating: AR coating

- AR coating: Ravg<0.5%a@working wavalength(6°AOI,single surface)

- Surface finish (scratches/pits): 40/20

- Plane flatness(@633 nm): λ/2

- Curved surface local aperture: 0.5

- Curved aperture; 3

- Eccentricity: ≤3 arcmin

-

- Optional materials: K9, N-BK7, JGS series UV fused quartz

- Working range: 400 nm-700 nm (other bands can be customized)

- Design wavelength: 546.1nm(n=1.519)

- Focal length tolerance: ±2%

- Shape tolerance: +0.0/-0.02mm

- Thickness tolerance: ±0.02mm

- Curved aperture: 3

- Plane flatness (aperture): 1

- Curved surface local aperture: 0.5

- Eccentricity: ≤3 arcmin

- Surface shape: 1/4λ@632.8nm

- Surface finish: National standard level 3, US military standard 60-40

- Clear aperture: >90%

- Safety edge: <0.2X45°

-

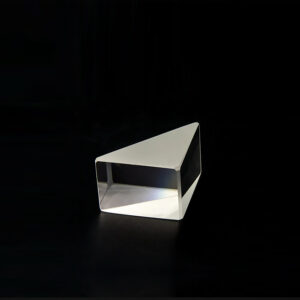

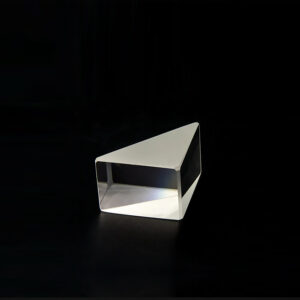

- Dimensional Tolerance (mm): ±0.1

- Bevel: Protective bevel as needed

- Substrate: N-BK7

- Coating Type: Metal

- Angle Tolerance (arcmin): ±2

- Power (fringes) @ 632.8nm: 1.25

- Irregularity (fringes) @ 632.8nm: 0.50

-

- Materials: UV Fused Silica

- Diameter Tolerance: +0.0/-0.1mm

- Mounting Ring Thickness: 3.5mm

- Unassembled Substrate Thickness: 2.0mm(Product thickness1.05mm)

- Substrate Thickness Tolerance: ±0.1mm(Thickness Tolerance ±0.05mm)

- Surface Smoothness: 60-40

- AOI: 0±5°

- Remark: The arrow on the mounting ring indicates the preferred direction of light propagation