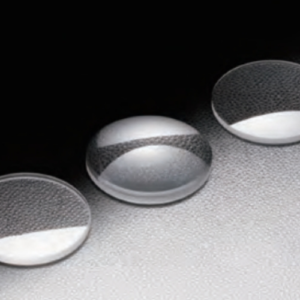

Aspheric Condenser Lenses

- Materials: UV Fused Silica

- Design wavelength 587.6nm

- Diameter error +0.0/-0.1mm

- Center thickness error ±0.2mm

- Surface irregularity: λ/4@632.8nm

- Effective focal length error ±2%

- Lens centering error: 3 arc minutes

- Surface finish 20/10~40/20

- Bevel : 0.2mmX45°

- Coating: Customization

Description

Introduction of Bote Aspheric Condenser Lenses

An aspheric condenser lens is a single lens used to focus light. Aspherical lenses are increasingly used in condensing systems. Usually condensing systems do not have ideal imaging requirements, and aspherical condensing lenses are inferior in terms of their processing accuracy.

Therefore, the focus of consideration on the processing technology of this type of aspheric lens should be on simplifying the processing procedures and improving work efficiency.

Considering the convenience of processing, we adopt the method of gradually grinding from the center to the 0.7 zone. The maximum asphericity is in the 0.7 zone.

The specific process (aspherical part) is as follows:

1.Milling

Mill the aspherical surface to be closest to the spherical surface and control the thickness.

2. Single piece rigid upper plate

3. Coarse grinding

Since the maximum asphericity is 0.65 mm, directly switching to fine grinding will reduce the efficiency due to the large machining allowance. Therefore, a profile grinding wheel is first used for rough grinding, as shown in Figure 2. The grinding wheel is made of white corundum with medium-soft hardness. The surface shape of the grinding wheel and the surface shape after rough grinding of the aspherical surface are guaranteed by the metal template.

4. Fine grinding

Use full-shape template tools. Because the aspherical surface is rough ground, the machining allowance is reduced, and fine grinding can easily ensure accuracy and improve work efficiency. The swing of the machine spindle during fine grinding is required to be controlled within 0.02 mm.

5. Polishing

Polished using a semi-full polishing die. As shown in Figure 3, the part rotates and the polishing mold swings slightly left and right. The central part of the aspherical surface is polished using an arc-shaped polishing wheel as shown in Figure 4.

Application

Bote aspheric condenser lenses have larger apertures, higher numerical apertures and lower f/# ratios than spherical lenses.

Therefore, these lenses are ideal for high-efficiency lighting applications or for collimating light from lamps, LEDs, or similar sources

Feature of Bote Aspheric Condenser Lenses

- Aspheric condenser lenses have larger apertures and higher numerical apertures than spherical lenses

- Available in 13 different diameters, ranging from 10 to 75 mm

- Numerical aperture from 0.52 to 0.79

- Available uncoated or coated with 350 – 700 nm or 650 – 1050 nm anti-reflective coating

- Made of B270 optical crown glass (380 – 2100 nm)

- High efficiency lighting applications

- Light collection/focusing

- Projection

- Detection

Reviews

There are no reviews yet.