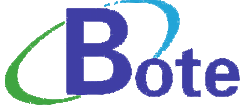

Laser Line Mirrors

- Materials: UV fused Silicon

Diameter: 25.4 mm

Thickness: 6 mm

Coating: High energy laser line reflective film

Reflection: Rs,Rp>99%@Designed wavelength

AOI:0-45°

Thickness Tolerance: ±0.25 mm

Diameter Tolerance: +0.0/-0.1 mm

Surface Finish(@633 nm)λ/10

Surface Smoothness: 10/5

Parallelism: <3 arcmin

Back Surface: precision frosted finish

Description

Introduction of Bote Laser Line Mirrors

Bote high-power laser line mirrors are manufactured with high Hawaiian photon and ultra-high laser damage damage value (LIDT) dielectric coatings, which can withstand high-energy pulses and damage thresholds.

The Bote high-power laser line reflector is efficiently optimized for a single wavelength range. The polarization resonance of the Bote high-power laser line reflector has better uniformity and noise thermal expansion coefficient, making it perform better during temperature fluctuations. , and have better tolerance to environmental impacts.

The working wavelengths of Bote high-power laser line mirrors include 266 nm, 355 nm, 532 nm, 780 nm, 1064 nm, 1550 nm and 532&1064 dual wavelengths. The estimated angle is 0-45°, and the reflectivity is as high as 99% or more.

Laser Mirror Reflection

Laser mirrors are precision-engineered optical components designed to reflect laser beams with high efficiency and minimal distortion.

Commonly used in laser systems, they ensure optimal performance in applications like medical devices, scientific research, and industrial cutting.

Our laser mirrors offer superior durability, high reflectivity, and low scattering for wavelengths across UV, visible, and infrared ranges.

Whether you need dielectric or metallic coatings, we provide customized solutions to meet your exact specifications. Enhance your laser system’s accuracy and efficiency with our reliable laser mirrors. Contact us today to learn more.

Features of Bote Laser Beam Mirrors

- Laser beam mirrors feature high reflectivity, low absorption, and excellent surface quality to ensure precise beam manipulation.

- Designed for durability, they are resistant to thermal and mechanical stress, making them ideal for high-power laser applications.

- With coatings tailored for specific wavelengths, these mirrors minimize energy loss and scattering.

- Common uses include laser cutting, medical devices, and research systems.

- Whether you need dielectric or metallic coatings, our mirrors deliver unmatched performance and reliability.

- Optimize your laser systems with our advanced laser beam mirrors—contact us today!

Reviews

There are no reviews yet.